In today’s fast-paced world, innovation waits for no one. Businesses need to move quickly from concept to market-ready products. But how can companies keep up with the demand for speed without compromising quality? The secret lies in choosing the right materials for prototyping. This blog post explores how versatile materials can be the key to streamlining product development, ensuring that your designs are not only quick to develop but also high in quality.

The Role of Prototyping in Product Development

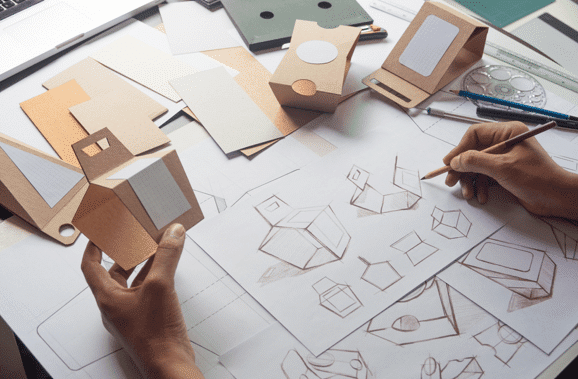

Prototyping is an essential step in product development. It allows designers to test ideas and troubleshoot potential issues early in the design process. Creating prototypes can help teams visualize concepts, communicate ideas, and gather valuable feedback. With this information, businesses can make informed decisions, reducing the risk of costly errors later on.

By experimenting with prototypes, teams can refine designs before moving to the final production phase. This process saves both time and resources, ensuring the final product aligns closely with customer needs and expectations.

However, the success of a prototype largely depends on the materials used. Selecting the right materials can significantly affect the prototyping process, speeding up development times and improving product quality.

Exploring Versatile Materials for Prototyping

When it comes to choosing materials for prototypes, versatility is key. Versatile materials can be easily shaped, molded, and adapted to various design needs. This flexibility allows designers to experiment with different ideas and make quick adjustments without starting from scratch.

For instance, lightweight plastics like ABS and PLA are popular choices for 3D printing prototypes. These materials are not only affordable but also easy to work with, making them ideal for rapid prototyping. Similarly, foam boards and cardboard offer simplicity and ease of manipulation, perfect for creating quick mock-ups.

Using versatile materials can significantly reduce the time and cost associated with traditional prototyping methods. By investing in adaptable materials, businesses can ensure their prototypes accurately reflect the final product’s functionality and appearance.

The Benefits of Streamlined Product Development

Streamlining product development offers numerous advantages. First and foremost, it accelerates time-to-market, giving businesses a competitive edge. With effective prototyping, companies can bring their products to market faster, capturing customer interest before competitors do.

Additionally, streamlined product development can lead to cost savings. Efficient prototyping reduces the need for multiple iterations, minimizing material waste and labor costs. This approach enables businesses to allocate resources more effectively, focusing on other critical areas of production.

Finally, a streamlined process enhances product quality. By identifying and addressing design flaws early, teams can ensure the final product meets high standards. This focus on quality not only improves customer satisfaction but also strengthens brand reputation.

How Versatile Materials Support Innovative Designs

Innovation thrives on experimentation. Versatile materials provide the flexibility needed to explore new ideas and push the boundaries of design. With adaptable materials, teams can quickly iterate and refine their concepts, paving the way for groundbreaking products.

For example, composite materials offer a unique combination of properties, such as strength and lightweightness. These characteristics make composites ideal for applications ranging from aerospace to consumer electronics. By leveraging these materials, designers can create innovative products that stand out in the market.

Furthermore, versatile materials can support sustainable practices. Many modern materials are environmentally friendly, offering recyclable or biodegradable options. By incorporating these materials into the prototyping process, businesses can reduce their environmental impact while maintaining high-quality standards.

Incorporating New Technologies into Prototyping

Technological advancements are reshaping the landscape of prototyping. Techniques like 3D printing and CNC machining enable precise and efficient production of prototypes. These technologies, combined with versatile materials, can revolutionize the product development process.

For instance, dye sublimation is an innovative printing technique that allows for high-quality, full-color printing on various materials. This technology is particularly useful for creating visually striking prototypes that closely resemble the final product. By incorporating such technologies into prototyping, businesses can produce realistic models that capture the true essence of their designs.

Integrating new technologies not only enhances the accuracy of prototypes but also opens up new possibilities for creativity and innovation.

Overcoming Common Challenges in Prototyping

While prototyping offers numerous benefits, it also presents challenges. One common issue is balancing speed with accuracy. Rapid prototyping techniques can sometimes compromise precision, leading to errors in the final product.

To overcome this challenge, it’s essential to choose the right materials and technologies. Versatile materials offer the adaptability needed to maintain accuracy without sacrificing speed. Additionally, investing in advanced equipment can ensure high-quality output throughout the prototyping process.

Another challenge is managing costs. While prototyping can be expensive, using versatile materials can mitigate this issue. These materials are often more affordable than traditional options, allowing businesses to stay within budget while achieving their design goals.

Case Studies Highlighting Success with Versatile Materials

Several companies have successfully implemented versatile materials in their prototyping processes, yielding impressive results. For example, a consumer electronics manufacturer used composite materials to develop a lightweight, durable prototype for a new smartphone. This approach allowed them to quickly iterate and improve the design, resulting in a highly successful product launch.

Another example comes from the automotive industry, where a car manufacturer utilized 3D-printed prototypes to test and refine vehicle components. By leveraging versatile materials, they reduced development time and costs, ultimately producing a more efficient and reliable vehicle.

These case studies demonstrate the power of versatile materials in streamlining product development and driving innovation.

Future Trends in Prototyping and Material Use

The future of prototyping is bright, with new materials and technologies continually emerging. Researchers are exploring the potential of smart materials, which can change properties in response to external stimuli. These materials could revolutionize the way prototypes are designed and tested.

Additionally, advancements in nanotechnology and biomaterials offer exciting possibilities for creating environmentally friendly prototypes. As sustainability becomes increasingly important, these materials will play a crucial role in shaping the future of product development.

By staying informed about these trends, businesses can remain at the forefront of innovation, ensuring their products meet evolving consumer demands.

Conclusion

In conclusion, versatile materials are essential for streamlining product development and fostering innovation. By incorporating adaptable materials into the prototyping process, businesses can accelerate time-to-market, reduce costs, and enhance product quality. With the right materials and technologies, companies can overcome common challenges and achieve their design goals more efficiently.

For businesses looking to stay ahead in the competitive landscape, investing in versatile materials and cutting-edge technologies is a smart strategy. These tools not only support innovative designs but also pave the way for a sustainable and successful future.If you’re ready to take your product development to the next level, consider exploring the potential of versatile materials and new prototyping technologies. By doing so, you’ll be well-equipped to create products that captivate consumers and stand out in today’s dynamic market.